Meet CPM: Biomass Technology with Global Impact

In this edition of Meet Our Members, we speak with Brock Harrington, Global Sales Director Alternative Fuels at CPM, a long-established leader in industrial equipment manufacturing. From their pioneering Direct Drive Pellet Mill to their focus on sustainable energy and global collaboration, CPM is helping shape the future of biomass processing.

Where are you based?

Alberta Canada. We moved here from Indianapolis to raise our kids in the small town where my wife grew up.

What does your company do?

CPM is a leading global manufacturer of equipment for various industries including Biomass and Feed and Oilseed and Industrial. Within the biomass industry, CPM empowers our customers to efficiently convert a wide range of organic materials into sustainable energy sources. Our robust technology facilitates the transformation of biomass into renewable energy, reducing waste and supporting global environmental goals.

What is your role at CPM?

What is your role at CPM?

As Global Biomass Sales Director, I lead our worldwide biomass sales team and manage major projects across multiple regions. I’m also responsible for our relationships with key pre-treatment technology partners and play a central role in delivering large-scale biomass solutions to customers around the world.

How is your team structured?

We operate with regional sales directors who support local representatives and agents across different markets. I directly manage the team in North America, where we focus primarily on capital equipment sales (pellet mills, hammer mills, and cooling systems) used in biomass production plants.

What value do your products and/or services bring to your customers?

Our equipment is designed for maximum uptime and reliability, even with the most difficult biomass feedstocks. We know that efficiency is critical for our customers, so our pellet mills and hammer mills are built to operate 24/7, 365 days a year. Over time, that translates into a low cost of ownership and consistent production performance.

How do your solutions support sustainability and innovation?

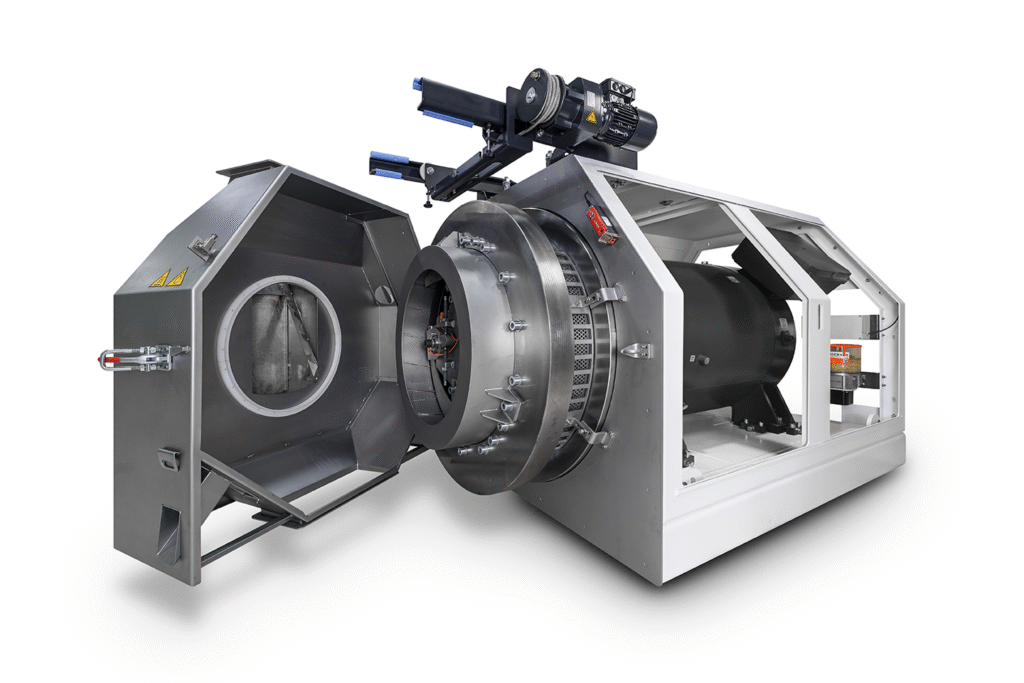

Sustainability and energy efficiency are central to our product development. For example, our latest Direct Drive Pellet Mills are the most energy-efficient in the industry, using the lowest kilowatt-hours per ton of production in the biomass sector. That’s a big step forward in terms of reducing operational emissions and improving energy use.

Looking Ahead: Technology and Innovation

What’s next for your company?

We’re excited about the launch of the world’s largest biomass-specific Direct Drive Pellet Mill, which we previewed at LIGNA 2025 in Hanover this past May. This new machine — with a 1200 mm die, 470 kW motor, and 60,000 Nm of torque — will be commissioned at a biomass plant in the USA this fall.

We’re also installing our DD660 model at the new torrefaction test center being developed by TSI/Fam in Georgia, USA — making it the first-ever Direct Drive Pellet Mill installed in a torrefaction plant globally.

Learn more about the Direct Drive Pellet Mill here: onecpm.com/product/direct-drive-pellet-mill

Any upcoming projects, innovations, or growth plans?

Absolutely, at CPM, we are continuously looking for innovative ways to assist our customers in overcoming their challenges. From research and development to world-class innovation centres and test labs, we’re dedicated to empowering customers to create better industrial operations, and therefore a better world.

Related Posts

-

SURE Certification System Updated for RED III

May 27, 2025